Process Design & Modeling

Design & Modeling Consulting

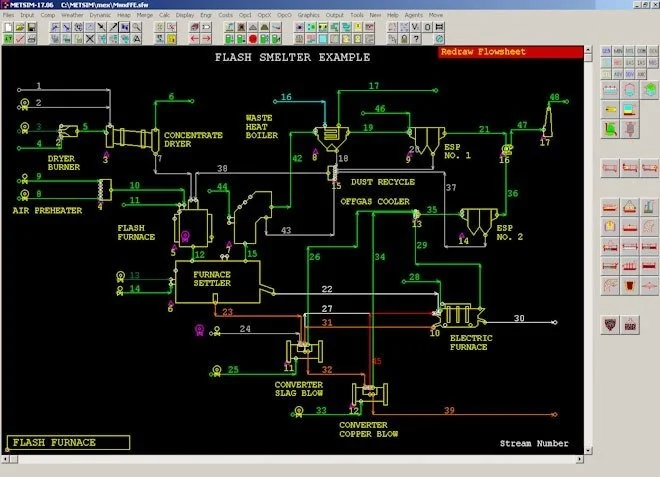

At Ghost Solutions, we specialize in advanced process modeling to help our clients unlock greater efficiency and performance in their operations. Using industry-leading tools like OLI and METSIM, we’re able to simulate complex chemical systems and full-process flows with precision.

OLI: Hydrometallurgy, aqueous and electrolyte chemistry, providing insight into:

Reaction dynamics

Scaling and corrosion

Asset longevity

METSIM: Analysis for chemical and metallurgical processes:

Mass and energy balance modeling

Analyze raw input to product output.

A high-fidelity process model ensures equipment is sized correctly and utilities are balanced before startup.

Our models reduce risk during design and prevent costly rework during commissioning.

What We Deliver

PCT-01 → PCT-05 Modeling Tiers Including:

Mass and energy balances

Block flow and process flow diagrams (BFDs & PFDs)

Thermodynamic and reaction modeling for key chemical and phase interactions

Equipment sizing and specification to validate process capacity and design basis

Utility and heat integration analysis for efficient steam, power, and water usage

Recycle and control loop closure to ensure realistic steady-state and operating conditions

Economic evaluation — CAPEX, OPEX, and ROI metrics tied to model results

Dynamic simulations of start-up, shutdown, and transient behavior for operations and training

Integration with PI data for real-time reconciliation, performance monitoring, and digital twin functionality

Validated process documentation — design basis reports, P&IDs, and simulation files ready for scale-up or handover

Clarity Before Commitment

Validate mass & energy balance

Optimized design parameters

Process flexibility

Right sized equipment

Fewer change orders

Improved safety and compliance

Predictive troubleshooting

Faster startups

Informed economics